Insights Blog

What is MES: An Introduction to Manufacturing Execution Systems and the SmartFactory.

Author: Dan Aldridge — PCG Director of Solutions Marketing

Intro to ERP and MES —

Enterprise Resource Planning (ERP) Systems date back all the way to the last century and really started dominating the market in the 1990’s. Back then, ERP vendors like SAP, Oracle, and Baan claimed to be everything to everybody. They said, “ERP has everything needed for manufacturers to run their businesses”.

The Shop Floor Control modules of these ERP systems were used to create production or work orders, which required manual recording of shop floor operators’ time, issuing materials from the warehouse or shop floor (work in process), and receiving finished goods back into inventory inside the ERP.

This was a time-consuming process, fraught with errors and delays in system processing. Without a Manufacturing Execution System (MES), what was in the ERP rarely, if ever, matched the reality on the shop floor.

How MES Empowers ERP: Bridging the Shop Floor to Top Floor —

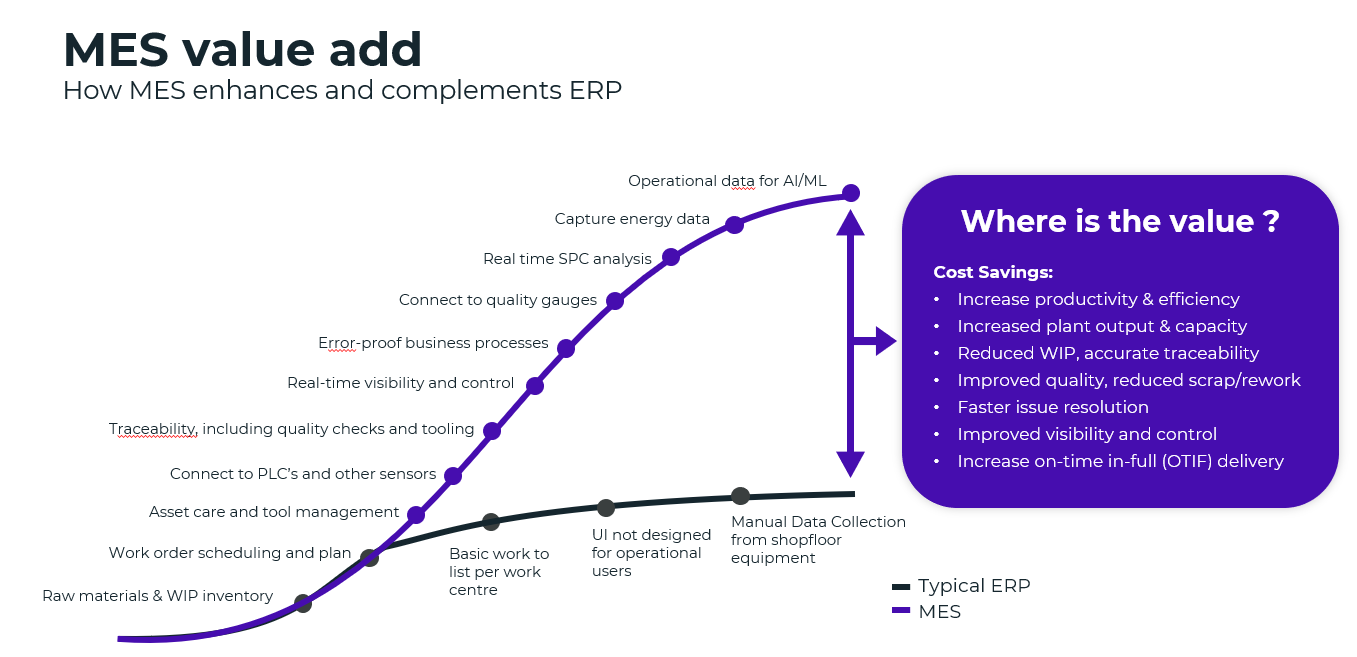

Today’s manufacturers rely heavily on ERP platforms to manage finance, supply chain, and business operations. Unfortunately, ERP systems can have blind spots on the shop floor.

This is where an MES can provide a solution. By connecting ERP with real-time production data, operators, and inventory, MES empowers ERP to deliver accurate data and actionable insights manufacturers need to operate predictably and cost–effectively.

Ideally, MES connects seamlessly to the ERP and provides automation and significantly more efficient shop floor execution with modules like:

-

- Shop Floor Execution

- Machine Monitoring

- Quality Management

- Compliance & CAPA

- Electronic Batch Records (eBR) and Kitting

- Connected Workers

- Production Management

- Finite Scheduling

- Materials Management

- ERP Connectors

- Reporting & Analytics

Below is a graph representing needed MES solution modules. Click here or on the image to get more SmartFactory™ information.

Why ERP Isn’t Enough for Manufacturers —

ERP systems are designed for enterprise planning, scheduling, procurement, order processing, and financial oversight. They’re excellent at answering questions like:

-

- What orders need to be fulfilled?

- What materials do we have on hand?

- What is our planned production schedule?

- What was our cost of goods sold this month?

Here’s the truth, though. ERP isn’t built to capture the day-to-day operations of the shop floor. Manufacturers face machine downtime, quality issues, and operator performance challenges that often go unrecorded until after an incident.

This lag in ERP processing results in missed deadlines, inaccurate cost tracking, and inefficient resource use, which is expensive in today’s market. Also, ERP alone isn’t connected to machine controllers or monitors on the shop floor, so it can’t provide predictive analytics or adapt when a plan meets “reality”. That reality may include machine downtime, operator absences, or just plain mistakes.

So, you NEED a strong MES to strengthen your faithful ERP in areas where it was never meant to go – despite what the ERP vendors tell you!

How MES Bridges the Key Gaps —

A Manufacturing Execution System integrates directly with machines, sensors, and operators on the shop floor, capturing and analyzing data in real time to create a live picture of production.

MES empowers manufacturers and their ERP systems by:

-

- Providing real-time visibility into production status, scrap rates, and performance.

- Aligning execution with planning by feeding accurate shop floor data back into ERP.

- Closing the loop between what ERP plans and what actually happens.

For example, suppose ERP schedules 1,000 units of production in a production or work order. MES will show production managers and operators how many of the 1,000 units were produced, exactly when, and at what quality level.

Similarly, if an ERP creates a production order with a complex Bill of Materials (BOM), an MES solution will ensure the necessary inventory is available when it’s needed, to keep production moving smoothly. Better than ERP alone, MES with ERP helps remove common production errors and optimize inventory levels.

The Benefits of a Combined ERP + MES Operation —

When MES and ERP work together, manufacturers see dramatic improvements, including:

-

- Accurate Data for Better Planning: Eliminate manual reporting delays with automated updates.

- Improved Decision-Making: Leaders base decisions on real-time shop floor performance, not estimates.

- Faster Response to Issues: Production managers can identify and correct issues immediately.

- Compliance & Traceability: MES maintains detailed audit trails that ERP can leverage for reporting and regulatory compliance.

- Much Better Key Performance Indicators (KPIs): Important KPIs such as Overall Equipment Effectiveness (OEE), predictive maintenance on machines, operator efficiency and quality/scrap can be measured easily and accurately.

Ultimately, MES ensures ERP delivers the “single source of truth” manufacturers strive for—backed by real-time data from the factory floor. This source of truth is not just financial, such as EBITDA, but it is also operational to give a better picture of productivity and the health of a company’s supply chain.

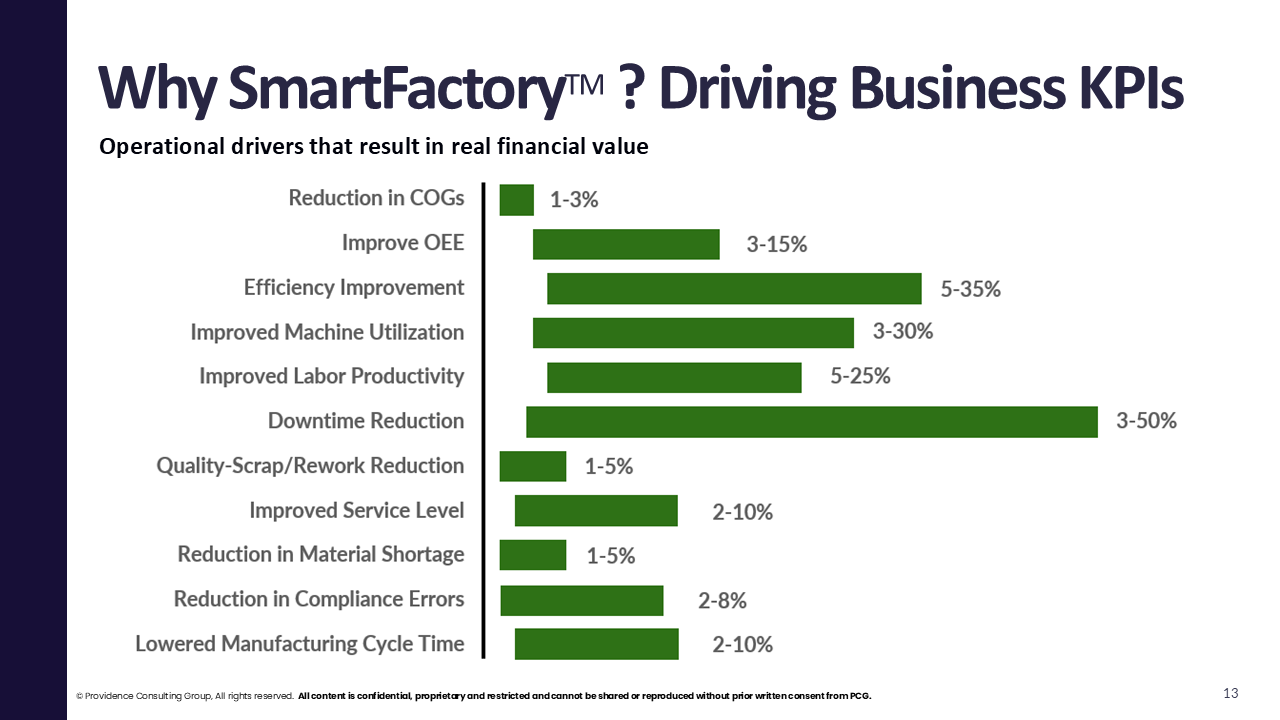

Our hundreds of customers report a wide range of improvements in their business key performance indicators (KPI’s) as shown in the graphic below. Some of the most impactful are:

-

- Up to 50% improvement in line and machine downtime.

- Up to 15% improvement in Overall Equipment Effectiveness (OEE), which is one of the most important measures of shop floor efficiency.

- Large increases in efficiency, machine utilization, and labor productivity which translates into cost savings and much better throughput.

Click on the graphic below to go to our PCG InsightsHUB page and find excellent demo videos for MES and SmartFactory™!

How PCG Enables Customers with ERP and MES —

At PCG, we have two excellent options for MES and SmartFactory, both of which have all the advantages discussed in this blog and more. Both options are tightly integrated with the ERP systems that we offer. We also have over 20 years of experience implementing ERP with MES enhancements.

Option 1: Is an advanced, cloud- and subscription-based SmartFactory solution. It has been developed, packaged, and integrated by PCG and includes all the modules and advantages noted in this article. SmartFactory is a smart manufacturing application, built on the Tulip platform, a top-ranked development platform.

On top of Tulip, we added functionality such as “Insights”, which is an AI agent-assisted business intelligence (BI) module that predicts events, such as when machines should be maintained.

We have created an entire website devoted to SmartFactory, located at asmartfactory.com.

Our Smart Factory solution runs on the Amazon Web Services (AWS) Commercial Cloud for non-government entities, such as commercial Aerospace, Automotive, or Industrial Manufacturing. It runs on the AWS Government Cloud for Aerospace and Defense manufacturers.

SmartFactory integrates seamlessly with the following top-ranked ERP systems:

-

- Infor CloudSuite Industrial Enterprise (CSIE/LN) for enterprise discrete manufacturers such as industrial manufacturing, automotive, aerospace and defense, electronics, life sciences, etc.

- Infor CloudSuite Industrial (CSI/SyteLine) for the same industries, only for SMB manufacturers.

- NetSuite ERP for manufacturers and other industries, such as pharma and biotech, mostly for SMBs but appropriate for some enterprises.

Option 2: Is an on-prem Infor MES solution. Infor MES is an on-prem option that is fully integrated with on-prem Infor ERPs, such as:

-

- Infor LN

- Infor SyteLine

- Infor XA

- And several other ERPs that can be converted to the CloudSuites…

Here is PCG’s page for our Perform MES, featuring Infor MES at its core.

We also have created a PCG InsightsHUB which has over 400 demo and thought leadership videos.

The InsightsHUB includes videos for (click title to access):

To get full VIP Access to the HUB, email Dan Aldridge.

Final Thoughts —

ERP is essential for planning and managing resources, but it was never meant to operate in isolation. By bridging ERP with shop-floor execution, MES gives manufacturers a powerful toolset to compete in an increasingly data-driven industry.

If your ERP feels disconnected from the realities of production, now is the time to explore how MES can bring your operations into sharper focus.

We hope you enjoyed “What is MES? An Introduction to Manufacturing Execution Systems and the Smart Factory”!

To stay up to date on the latest information, follow PCG on LinkedIn.

///

Dan Aldridge

Dan has 25+ years of corporate management experience including CEO, CFO and Controller of the consulting firm he founded and grew for 13 years. He has ERP software and digital transformation experience working with CEO’s, CFO’s, Controllers, and other C-levels at Fortune 500 companies. He specializes in Finance (e.g., Financial Statements, General Ledger, Accounts Payable, Cost Accounting) and Manufacturing (e.g., MRP, Production, Industry 4.0, Smart Factories, MES systems) consulting and project management.

Work together with PCG for great Infor platform success. Contact us, and let’s get started!

More Information for You

Solutions

Services

Support

Platforms

Technology Partnerships

Contact | Legal | Privacy Policy | LinkedIn | YouTube | SmartFactory | OrangeQuery