Welcome to Sustainable Manufacturing Operations.

Integrating manufacturing businesses from the top floor to the shop floor for end-to-end operational and cost control.

Manufacturing Execution Systems that Perform.

Manufacturers and suppliers face increasingly complex requirements for materials, components, inventory management, and supply chain integration.

With tight margins and increasing pressure for innovation and new products, moving beyond traditional ERP becomes critical to future success.

At the intersection of demand and profitability is Industry 4.0, MES, and integrated analytics that put you in control of your shop floor, back office, supply chain information, and information for making the best investment and operational decisions.

PCG’s innovative Industry 4.0 and MES services bring together and harness the power of information from manufacturing equipment, business processes, the supply chain, innovation, and product design efforts, along with financial information, to give you a complete picture of the business—leading to fast, accurate decisions and a more profitable operation.

PCG’s Industry 4.0 solution is a comprehensive, proven suite of technical and business knowledge, manufacturing platforms (from the back office to the shop floor), process and information experience, models, and methods designed for speed, accuracy, and lower project cost and a track record of customer success around the world.

PCG is the only logical Industry 4.0 and MES choice for consulting, implementing, and optimizing your manufacturing business. Don’t make costly business and performance mistakes. Go with the right partner. Choose PCG.

We Bring Manufacturing Technologies to Life

ERP, SCM, PLM, MES, EAM, EPM, ADVANCED ANALYTICS AND BUSINESS INTELLIGENCE, AI, ML, SMART FACTORY, INTELLIGENT MANUFACTURING, ADVANCED DISTRIBUTION, DATA LAKES, MOBILITY, EDGE APPLICATIONS, BUSINESS PROCESS IMPROVEMENT, CHANGE MANAGEMENT, SCADA, REGULATORY COMPLIANCE, DIGITAL AND BUSINESS TRANSFORMATION, AND MORE.

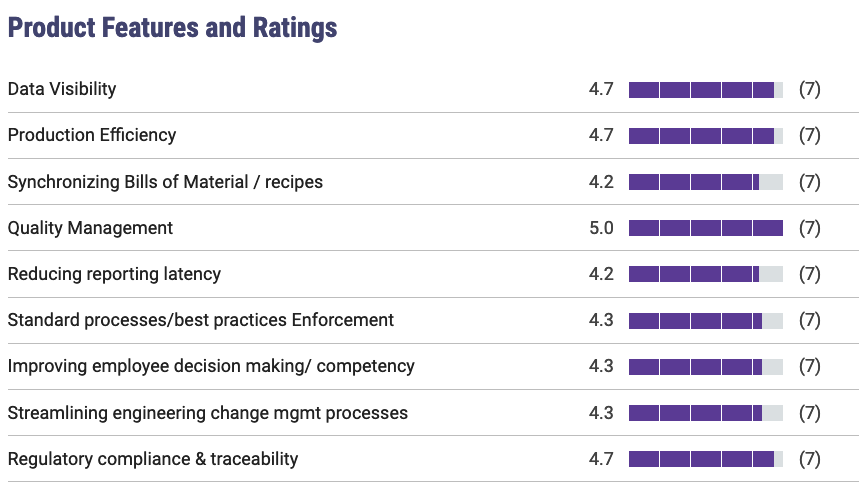

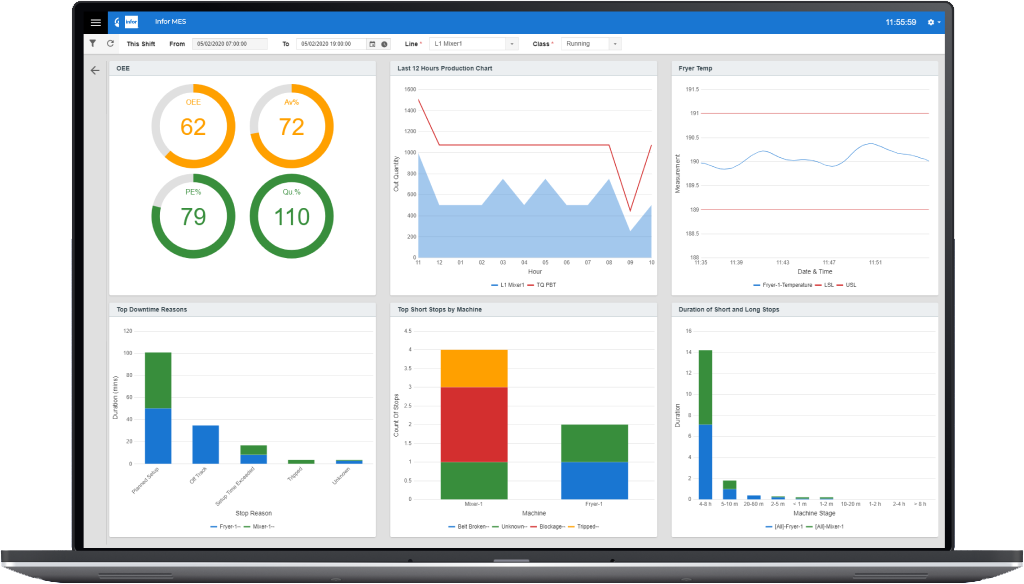

PERFORM MES Benefits

-

- Real-time insights from the shop floor to the back office

- Detailed performance and KPI reports to find new improvements

- Sophisticated visualizations for better production control

- Automated incident alerting for fast corrective actions

- Integration from machines to ERP and analytics

- Mobility through smart device support

Common Manufacturing Challenges

-

- 95% of manufacturing executives do not have complete, cross-enterprise integration of their information

- 83% of manufacturing business can’t determine the cost of operational downtime

- 76% of manufacturing companies have no access to real-time information

- 61% manually produce reports, combining data from different systems

- Only 12% have the information and tools to do production issue root cause analysis

Make MES Happen in Your Operation.

Services